Downspout pipe roll forming machine

1.Technical Parameter

- Machine specification: forming thickness(0.5-0.6mm)xL, yield

strength≤G250Mpa

-

- Forming speed: 12-15M/min (EXCLUDING CUTTING STOP TIME)

- Forming roller: about 20 groups

- Main motor power: 7.5KW

- Hydraulic station power:4KW

- Roller material: 45# forged steel, surface coated with chrome

- Main shaft material: 45# steel

- Main axis dia.: ¢68mm

- Hydraulic cutting pressure: 10-12Mpa

- Cutting method: hydraulic powered, cutting after roll forming.

- Cutting blade material: Cr12 quenching treatment

- Electrical controlling system: Whole line adopted PLC control, cut

to length tolerance≤2mm

2.Main Components

| Machine List | 3 tons manual de-coiler | 1 set |

| Infeed guiding | 1 set |

| Main roll forming machine | 1 set |

| Straighten device | 1 set |

| Hydraulic cutting equipment | 1 set |

| Output table | 2 sets |

| Main drive | 1 set |

| Hydraulic system | 1 set |

| Controlling system (including cabinet) | 1 set |

| Downpipe elbow forming machine | 1 set |

| seaming machine | 1 set |

3.Working Flow of Roll Forming Machine

A. Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B. Servo Feeding

Applicator............................................To feed the

material accurately

C. Hydraulic/Press

Punching...........................................To punch as

requirements

D. Roll Forming

Unit.........................................................To

roll form as requirements

E. Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F. Output

Table................................................................Support

the finished products

4. Advantage for Roll Forming Machine

During the warranty period, maintain and change the spare parts for

the customers for free (except for the instrument damage caused by

human factors or natural disasters. ) And provide technical support

for life-long.

We can design and manufacture the machine according to clients'

request! Our machines have passed CE, Guaranteed quality. Please

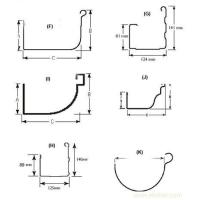

send us the enquiry with Profile Drawing.

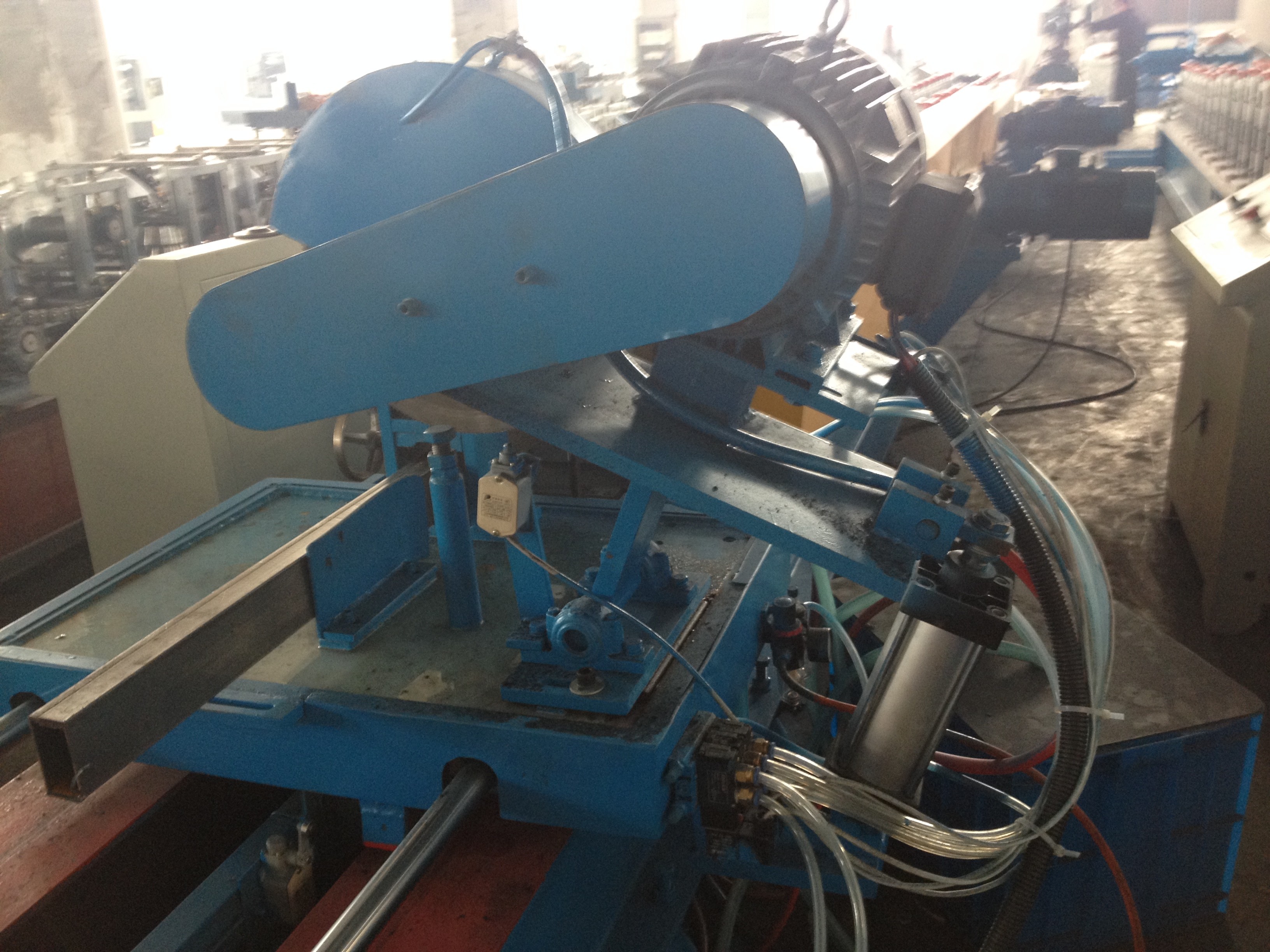

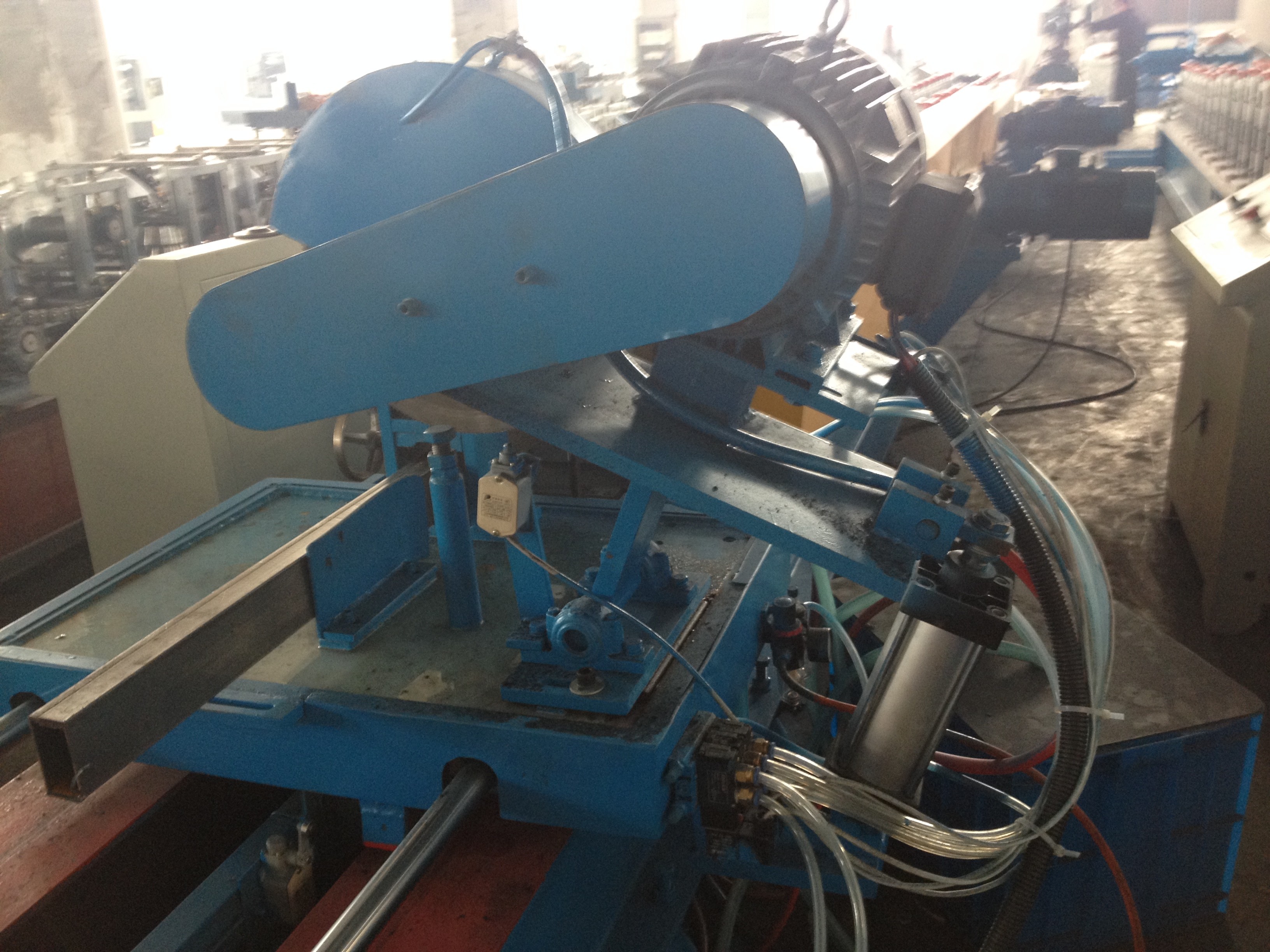

5. Photo Gallery

6. Loading picture

After-sale Serive

- The seller take responsibility to installation and commissioning

of the equipment and free training. After machine arrive the

destination, by the request of the buyer , the seller will provide

1 technical engineer to guide installation and training , and the

buyer should give the technical person with full cooperated.

- Installation period: about 5 days after the complete preparation

by the buyer such as the foundation and all necessary accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the buyer should

pay for installation and commissioning fee 100$/day to the point

account of the seller. The two-way ticket,visa, food, hotel , the

translator and insurance are all should provide by buyer with full

responsibility.

-The seller supply technical data (including forming mould drawing,

electrical elements drawing and equipment drawing etc.)