Sussman Machinery(Wuxi) Co.,Ltd

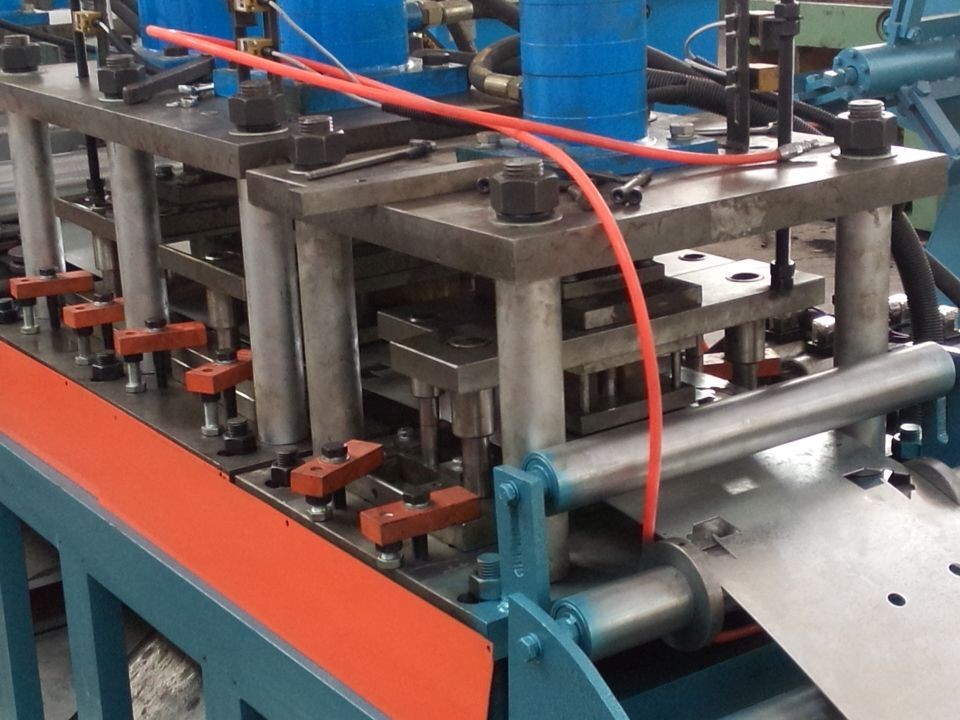

The main products of factory is light gauge framing machine,

pre-painted steel forming machine, Glazed Tile forming machine,

Automatical C/Z Purlin forming machine, Floor Deck forming machine,

Guardrail forming machine, Down Pipe forming machine, The whole

carriage plate for car beam unit , Steel storage unit, etc. Totally

it has 100 types in 20 serious. The products are widely used in

warehouse, factory buildings, supermarket, Nursing homes, villas,

residential, greenhouse and other construction projects. Our

factory can meet the construction enterprises, automobile industry,

iron and steel production enterprises’s growing demand.