Servo Feeding Device Upright Frame Cold Roll Forming Machine 11 kw

Main Roll forming machine technique data

Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or

blank steel

Working Speed: 12-15 meters / min

Forming Steps: 18 stations

Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal

refining

Driven system: Chain Driven 1.5 inches 20A double chain with longer

shafts

Main Power with reducer: 11KW WH Chinese Famous

Cutting: Hydraulic Cutting Cr12mov

Material of Cutting Knife: Cr12Mov, Quench HRC58-62

Hydraulic Station Power: 7.5KW Wuxi Wanshen Famous Chinese Brand

The whole machine is controlled by industry computer-PLC.

PLC--Panasonic, Japan English and Chinese Language

Touch Screen--Panasonic Japan

Encoder--Omron, Japan

Electric parts--Schneider

Cutting holder: straight cutting by 3 pieces of blades

Main Components

No. | Item Name | Quantity | Remark |

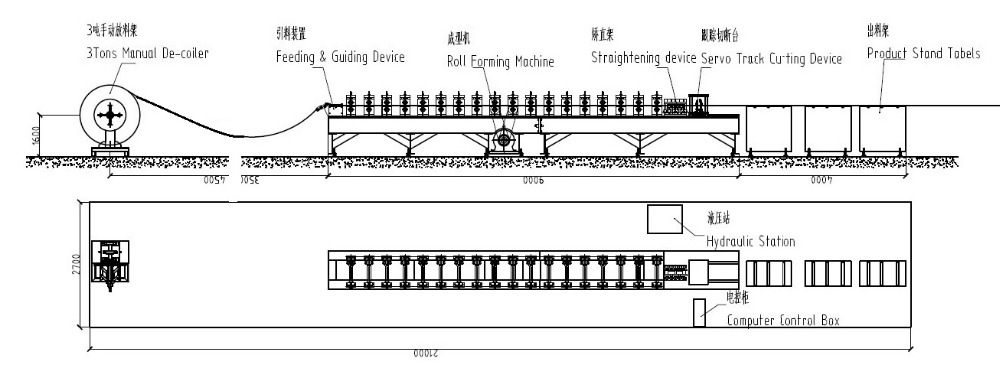

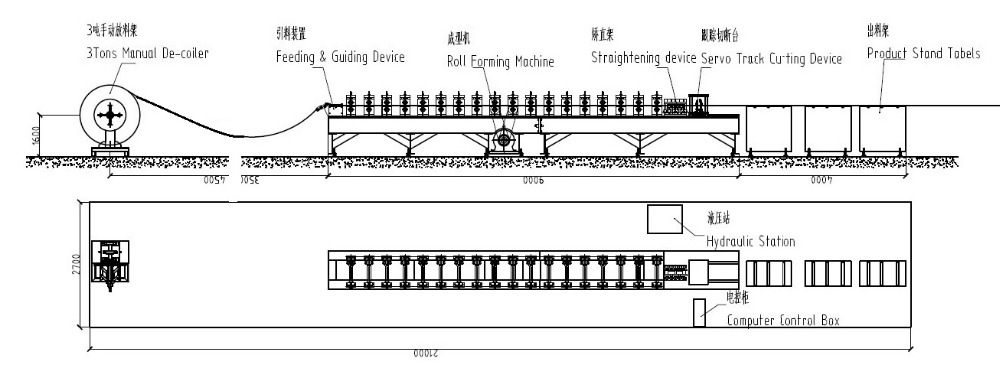

1 | Manual de-coiler | 1 set | 3 tons |

2 | Leveling machine | 1set | Wannan motor |

3 | Cutting device | 1 set | Engineer define |

4 | Punching device | 2 sets | Hydraulic Prepunching |

5 | Roll Forming Machine | 1 set | ¢75mm |

6 | Cutter mold | 6 units | Engineer define |

7 | Hydraulic station | 1 set | Engineer define |

7 | Product stand table | 5 sets | 2 m*5 |

8 | Folded machine | 1 set | ¢75mm *4 |

9 | Tool Box | 1 box | standard |

10 | Books | 1 book | Use manual, Wire diagram, Machine layout drawing, Maintenance book, |

11 | Spare parts | 1 set |

|

Roll Formed Pallet Rack Advantages:

- Adaptable: Adapts to the weight, volume and size of many products and the

teardrop style is interchangeable among different manufacturers.

Excellent for warehouses storing products with varying sizes.

- Convenience: A boltless, easy to assemble product. Provides great stock

management with direct access to each pallet. Because the clips can

be moved quickly, shelves can be easily changed to accommodate

various heights and load sizes.

- Cost-Effective: Less expensive and more adaptable than structural steel racks,

the cost provides a good return on investment. The roll-formed

design, using flat rolled carbon steel, still provides strength

necessary for most applications.

Working Flow of Roll Forming Machine

Manual de-coiler-->leveling machine -- roll forming machine

–Cutting device–>Product Stand Tables

Photo Gallery

Production process

Why choose us