Main Roll forming machine technique data

1. Suitable Plate Material: thickness 1.5-2.5mm, Galvanized steel or blank steel

2. Working Speed: 10 meters / min

3. Forming Steps: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Gear box

7. Main Power with reducer: 15KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

11. The whole machine is controlled by industry computer-PLC.

| Model number | Rack Roll Forming Machine |

| Material Thickness | 1.5-2.5mm |

| Product speed | 0-10meter / per minute |

| Roller Stations | About 18 stations |

| Roller Material | Gcr15 Steel with quenching |

| Shaft Material | 45# Advanced Steel (Diameter: 76mm), thermal refining |

| Material Of Cutting | CR12Mov with quench treatment |

| Electronic control | PLC control with touch screen |

| Weight | About 10 tons |

Machine parts list

| S.N | Equipment name | Quantity |

| 1 | 3T hydraulic un-coiler | 1 set |

| 2 | Leveling device 400mm | 1 set |

| 3 | Servo feeding device 400mm | 1 unit |

| 4 | Press machineJH21-80 | 1 unit |

| 5 | Main roll forming machine 18 stations | 1 set |

| 6 | Cutting holder | 1 set |

| 7 | Hydraulic station | 1 set |

| 8 | Control system ( including control box) | 1 set |

| 9 | Out tables | 2 units |

| 10 | Spare parts | 1 package |

| 11 | Hydraulic Cutting die | 1 set |

| 12 | Punching die set | `1 set |

Machine Layout

Machine Shows

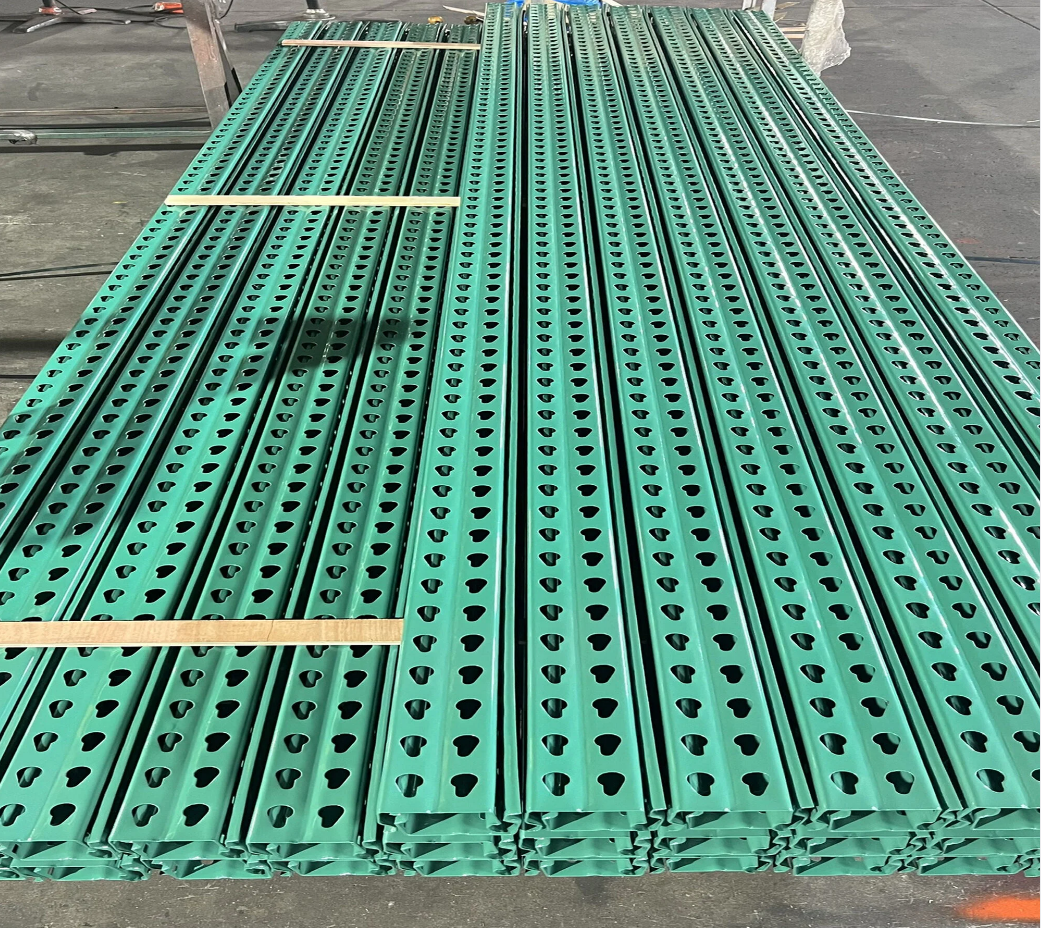

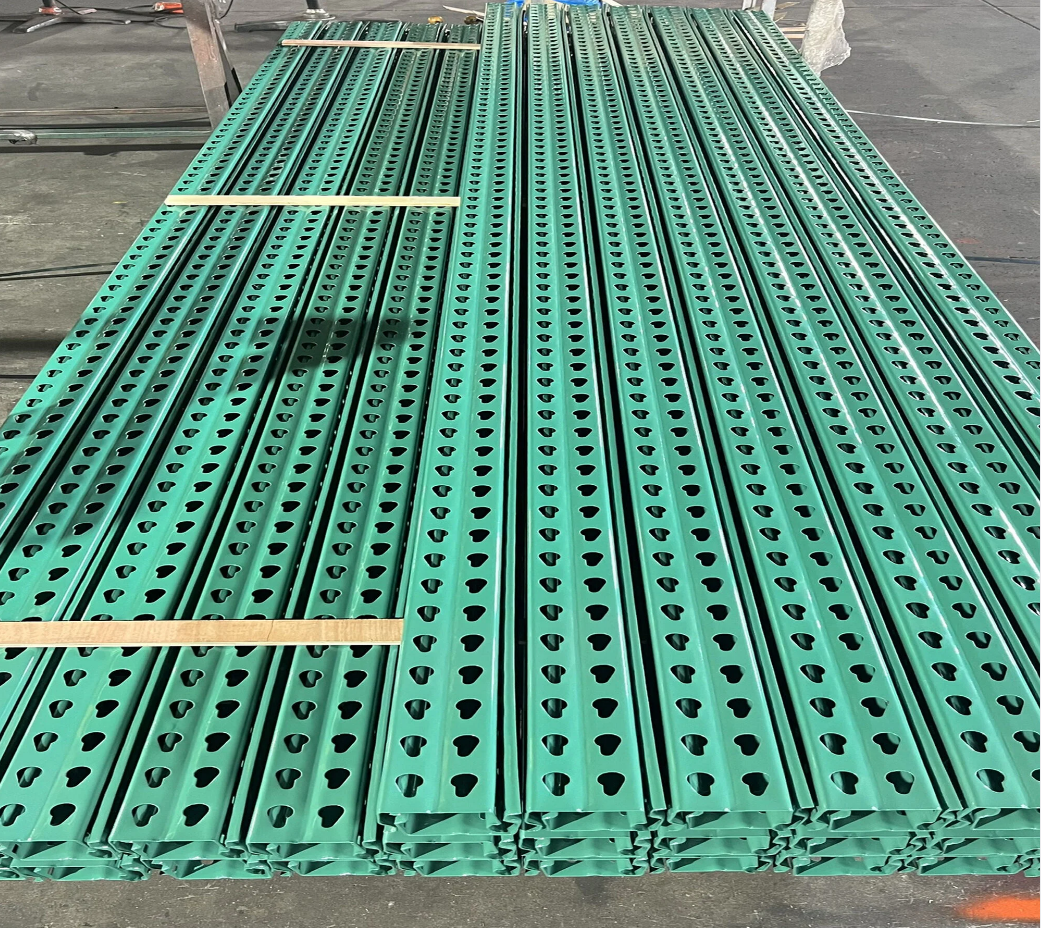

Finished Products:

Application

The upright rack, also known as a pallet rack or selective rack, is a common storage system used in warehouses, distribution centers, and other industrial environments. Its main application is to provide efficient and organized storage for palletized goods. Here are some specific applications of upright racks:

1.Pallet storage: The primary purpose of upright racks is to store palletized goods. They are designed to accommodate standard pallet sizes and can hold a large number of pallets vertically, maximizing vertical storage space.

Warehouse organization: Upright racks help in organizing a warehouse or distribution center by providing designated locations for specific products. This makes it easier for workers to locate and access items, reducing the time and effort required for inventory management and order picking.

2.Inventory management: Upright racks facilitate inventory management by providing clear visibility and accessibility to stored items. By using labeling systems and organizing products by SKU or category, it becomes easier to track and manage inventory levels, improving overall inventory accuracy.

3.Order picking: Upright racks play a crucial role in order picking processes. They allow for efficient and systematic picking of products, enabling workers to quickly locate and retrieve items for customer orders. This helps to streamline order fulfillment and improve order accuracy.

4.FIFO/LIFO storage: Upright racks can be used to implement inventory management methods such as First-In-First-Out (FIFO) or Last-In-First-Out (LIFO). By configuring the racks accordingly, it is possible to ensure proper rotation of inventory and minimize product obsolescence.

5.Safety and protection: Upright racks are designed to provide stability and safety for stored goods. They often incorporate safety features such as beam connectors, load stops, and backstops to prevent pallets from falling or shifting. Additionally, accessories like wire mesh decking can be added to enhance safety and protect against falling objects.

Overall, upright racks are essential for efficient storage and organization of palletized goods in industrial environments. They enable businesses to optimize space utilization, improve inventory management, and enhance overall warehouse operations.