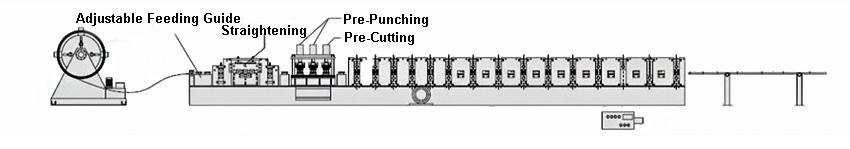

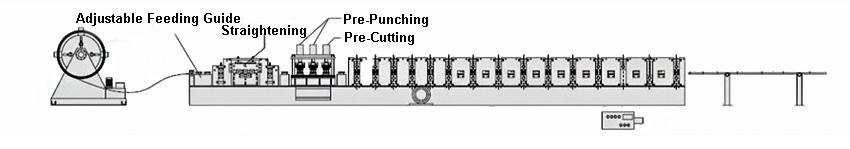

C Purlin Machine Description:

Process Flow of C Purlin Roll Forming Machine

Uncoiler --- Feeding --- Straightening --- Pre-punching ---

Pre-cutting --- Roll Forming --- Exit Rack

Uncoiler --- Feeding --- Straightening --- Roll Forming --- Post

Punching --- Post Cutting --- Exit Rack

Technical Parameters:

| Parameter | Description |

|---|

| Material thickness | 2.0-3.0mm |

|---|

| Width | 100-300mm adjustable automatically |

|---|

| Roller Material | 45# Steel |

| Control System | PLC Control System |

| Weight | About 10T |

| Cutting Type | Hydraulic Cutting |

| Forming Speed | 8-12m/min |

| Color | Customized |

| Length Measurement | Encoder Measurement |

| Material | Galvanized Steel |

| Total Power | About 18.5KW |

| Machine Type | CZ Purlin Making Machine, CZ Purlin Rolling Machine, Cee Zee Purlin

Machine |

Machine Configurations of C Purlin Roll Forming Machine

| 1. Hydraulic Uncoiler | 2. Feeding Device |

| 3. Straightening | 4. Roll Forming Machine |

| 5. Hydraulic Punching | 6. HydraulicCutting |

| 7. PLC Control System | 8. Out put table |

| Model | C Section Size (mm) | Hole Distance | Remark |

| H | B | B | C | t | h |

| C100 | 100 | 40 | 40 | 15 | 2.0.3.0 | No Punching | We Can Design the Machine According to Customer's Requests (with

Middle Hole Punching). |

| C120 | 120 | 50 | 50 | 20 | 2.0-3.0 | 40 |

| C140 | 140 | 50 | 50 | 20 | 2.0-3.0 | Adjustable Hole Distance |

| C160 | 160 | 60 | 60 | 20 | 2.0-3.0 |

| C180 | 180 | 60 | 60 | 20 | 2.0-3.0 |

| C200 | 200 | 60 | 60 | 20 | 2.0-3.0 |

| C220 | 220 | 70 | 70 | 20 | 2.0-3.0 |

| C250 | 250 | 70 | 70 | 20 | 2.0-3.0 |

| C300 | 300 | 80 | 80 | 20 | 2.0-3.0 |

Applications:

The finished products are widely used as the supporter of roof and

wall in large-scale and mid-scale construction, such as factory,

industrial buildings, balcony, and garages, warehouse, garage,

exhibition center, cinema, theatre, garden and so on.

Support and Services:

Technical Support and Service for C Purlin Roll Forming Machine We offer comprehensive technical support and service to our

customers for C Purlin Roll Forming Machine. Our team of

experienced engineers and technicians ensure that you receive the

best possible service for your C Purlin Roll Forming Machine. Our

technical support and service includes:

- Installation and setup of the C Purlin Roll Forming Machine

- Periodic maintenance and service

- Troubleshooting of the C Purlin Roll Forming Machine

- Training of your personnel

- Advice on the best use of the C Purlin Roll Forming Machine for

your production

We are committed to providing you with the highest quality service

and support for your CZ Purlin Roll Forming Machine. If you have

any questions or concerns, please do not hesitate to contact us.

Machine photo