0.3-0.8mm Thickness Beam Standing Roll Forming Machine Metal Roof

Tile Making Machine

A metal standing seam is a type of roofing system that consists of

continuous panels that run vertically from the ridge of the roof

down to the eaves. These panels are joined together with raised

seams, which interlock to create a sleek, uniform appearance. The

term "standing seam" refers to the prominent seams that stand up

vertically from the flat surface of the panels.

Here are some key features and benefits of metal standing seam

roofing:

Key Features:

1. Interlocking Seams: The seams of the panels interlock, often

with a hidden fastener system, which helps prevent water

penetration and enhances the roof's durability.

2. Vertical Panels: Panels run vertically, from the ridge to the

eaves, providing a clean, modern look.

3. Material Options: Common materials include galvanized steel,

aluminum, zinc, and copper, each offering different benefits in

terms of durability, appearance, and cost.

4. Coatings and Finishes: Panels can be coated with various

finishes to enhance their resistance to weathering and corrosion,

as well as to provide different color options.

Benefits:

1. Durability: Metal standing seam roofs are highly durable and can

last 40 to 70 years or more, depending on the material. They resist

cracking, shrinking, and eroding, making them suitable for various

climates.

2. Weather Resistance: The interlocking seams provide excellent

protection against rain, snow, and wind, making these roofs highly

weather-resistant.

3. Energy Efficiency: Metal roofs can reflect solar radiant heat,

reducing cooling costs by up to 25%. Many metal roofing systems

also include cool roof coatings that enhance their reflective

properties.

4. Low Maintenance: These roofs require minimal maintenance

compared to other roofing types. Periodic inspections and minor

repairs are usually sufficient to keep them in good condition.

5. Aesthetic Appeal: Standing seam roofs offer a sleek,

contemporary look that can enhance the architectural style of

various buildings, from residential homes to commercial structures.

6. Eco-Friendly: Metal roofing materials are often made from

recycled materials and are fully recyclable at the end of their

life cycle, making them an environmentally friendly option.

Applications:

Metal standing seam roofing is used in a variety of settings,

including:

- Residential Buildings: Many homeowners choose standing seam roofs

for their durability, low maintenance, and modern aesthetic.

- Commercial Buildings: These roofs are common in commercial

applications due to their long lifespan and ability to withstand

harsh weather conditions.

- Agricultural Buildings: Metal roofs are ideal for barns and other

agricultural structures because they provide excellent protection

and require minimal upkeep.

Overall, metal standing seam roofing is a versatile and durable

option that offers numerous advantages for both residential and

commercial buildings.

Standing Beam Bottom Technical Parameter

1. Steel Sheet Thickness: 0.3-0.8mm (depend on requirement )

2. Transmission way: single chain

3. Transmission material: 45# steel, high frequency quenching,

circular pitch: 38.1, number of teeth:13

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 5 ton passive decoiler

6. Forming Speed: 0-12m/min

7. Roller Groups: 16 stations

8. Roller Material: 45# steel, high frequency quenching treatment,

HRC58-62

9. Material: galvanized steel, color coated steel

10. Principal Axis: 45# high grade steel with quenching treatment

11. Main Motor Power: 7.5 Kw

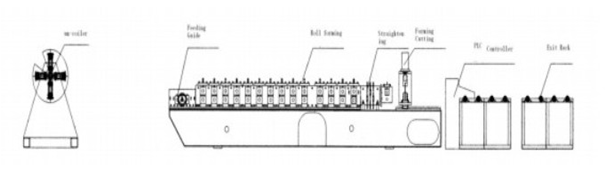

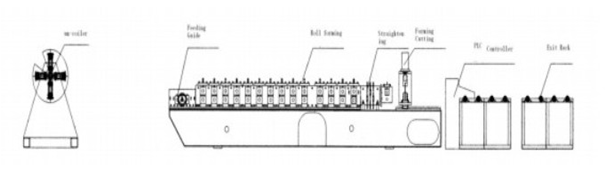

Standing Beam Main Components

| S.N | Equipment name | Quantity |

| 1. | 5T passive un-coiler | 1 set |

| 2. | Feeding and leveling device | 1 set |

| 3. | Main roll forming machine 18 stations

| 1 set |

| 4. | Hydraulic cutting | 1 set |

| 5. | Control system (including control box) | 1 set |

| 6. | Out tables | 2 sets |

| 7. | Hydraulic station | 1 set |

| 8. | Seamer device | 1 set |

Advantage for Standing Beam

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Working Flow of Standing Beam

Decoiler----Feeding and Leveling---Roll forming---Cutting---Run out

tables

Profiles of Standing Beam

Company Introduction

Sussman Machinery (wuxi) Co., Ltd. is a comprehensive enterprise

integrating production, sales and services. We are mainly engaged

in providing machineries and equipment. Owing to a professional

teamwork, we are experienced in manufacturing, import and export,

customers' design, installation and test, technical solution and

after-sale services. We have shipped out our machines to more than

50 countries, and keep good business relationships with a large

amount of worthy customers, contributing to our great business

records and reputation.

Loading Pic.