Chile Popular 26 GA 5V Roof Panel Roll Forming Machine Metal Roof

Sheet Making Machine

Metal roof sheets are a popular choice for both residential and

commercial buildings due to their durability, longevity, and

aesthetic appeal. Here are some key points about metal roof sheets:

Types of Metal Roof Sheets

1. Corrugated Metal Sheets:

- Recognizable by their wavy pattern.

- Often used for agricultural buildings and sheds.

2. Standing Seam Metal Roofs:

- Characterized by raised seams running vertically from the roof's

ridge to the eaves.

- Common in modern architectural designs.

3. Metal Shingles:

- Mimic the appearance of traditional roofing materials like slate,

wood, or tile.

- Offer a more classic look while providing the benefits of metal

roofing.

Materials

- Steel:

- Often coated with a layer of zinc (galvanized) or a mix of zinc

and aluminum (Galvalume) to prevent rust.

- Durable and cost-effective.

- Aluminum:

- Lightweight, resistant to rust, and ideal for coastal areas.

- More expensive than steel.

- Copper:

- Offers a distinctive aesthetic and develops a patina over time.

- Very durable but also one of the most expensive options.

- Zinc:

- Long-lasting and self-healing, meaning scratches will mend over

time.

- Like copper, it's quite expensive.

Benefits

- Durability:

- Metal roofs can last 40-70 years, depending on the material.

- Weather Resistance:

- Can withstand high winds, rain, snow, and even fire.

- Energy Efficiency:

- Reflects solar radiant heat, reducing cooling costs.

- Low Maintenance:

- Requires less maintenance compared to traditional roofing

materials.

Considerations

- Initial Cost:

- Higher upfront cost compared to asphalt shingles.

- Noise:

- Can be noisier during rain or hailstorms, although proper

insulation can mitigate this.

- Expansion and Contraction:

- Metal expands and contracts with temperature changes, which can

lead to issues if not properly installed.

Installation

Proper installation is crucial to ensure the longevity and

performance of a metal roof. It is recommended to hire experienced

professionals who understand the specific requirements of metal

roofing systems.

Conclusion

Metal roof sheets offer a robust, long-lasting, and aesthetically

versatile roofing option suitable for a wide range of applications.

Whether for residential homes, commercial buildings, or

agricultural structures, the various types and materials available

can meet diverse needs and preferences.

Technical parameter:

| Number | Items | UnitType | RF-DL |

| 1 | Steel Thickness | mm | 0.12-0.3mm 0.3-0.8mm PPGI and GI |

| 2 | Forming line Speed | m/min | 10-12 |

| 3 | Roller stands | stand | About 20-22stands |

| 4 | Roller Material | mm | #Gcr15, coated with hard chrome quenching |

| Shaft material and diameter | mm | Ф76 45# steel, coated with chrome |

| 5 | Main Motor Power | Kw | 7.5 |

| 6 | Hydraulic cutting Power | Kw | 4 |

| 7 | Hydraulic pressure | Mpa | 12 |

| 8 | Power Supply | | 415V, 50HZ,3 phase |

| 9 | Tolerance | mm | +/-1.5 |

| 10 | Material of cutting | | Cr12mov HRC60-62 |

| 11 | Control system | | PLC with touch screen |

| 12 | Machine net weight | T | 8 |

| 13 | Out size | mm | 10000*1300*1000 |

Machine List

| Machine list | 5 tons hydraulic de-coiler | 1 set |

| Main roll forming machine | 1 set |

| PLC Control box | 1 unit |

| Hydraulic station | 1 unit |

| Safety cover | 1 set |

| Spare parts | 1 set |

working flow

Profile Drawing

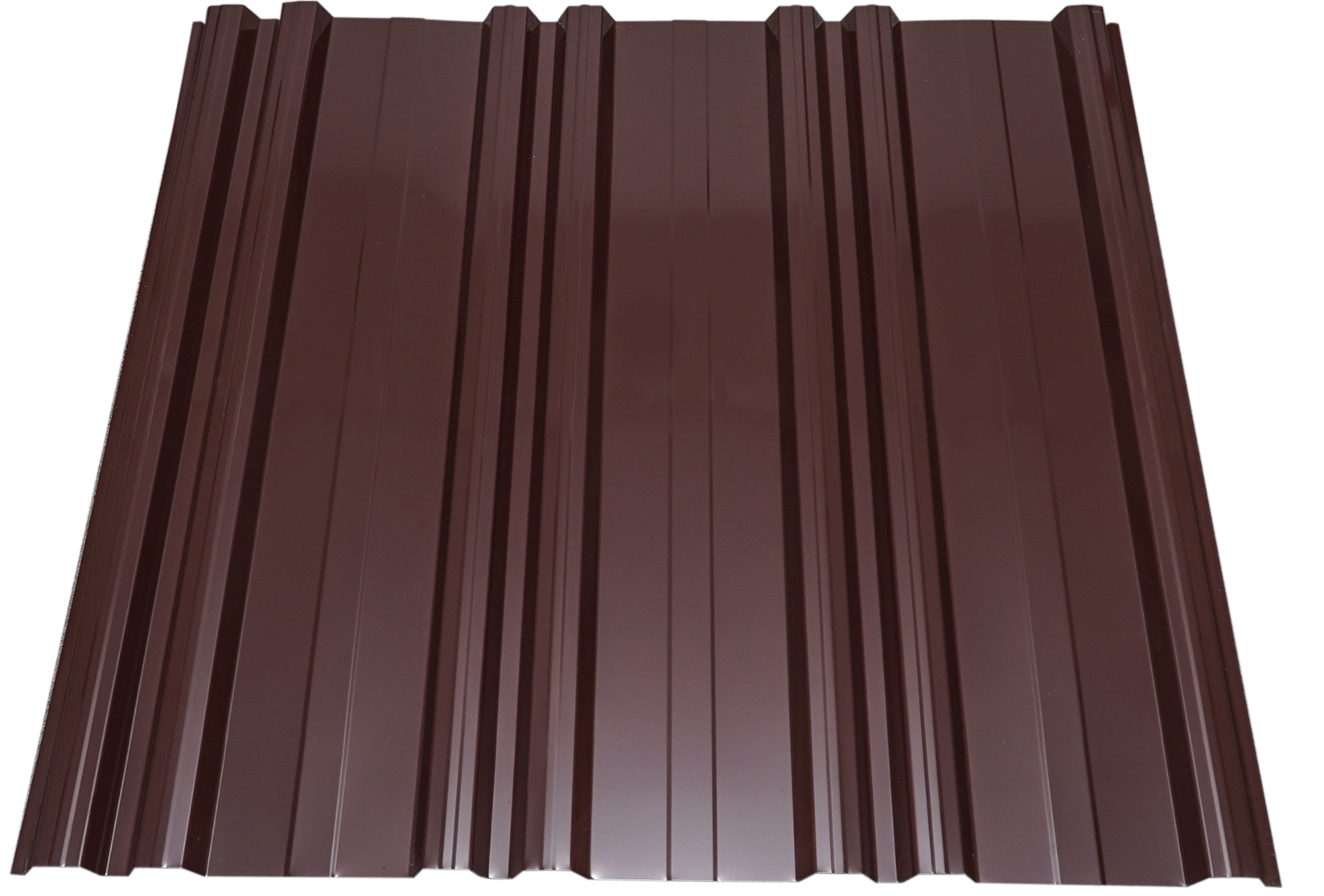

5V Crimp is most common in residential settings but is also

suitable for light commercial applications.

The 5V Crimp roof panel offers an ideal old-time, residential

appearance.

5V Crimp is also an aesthetically-pleasing solution for light

commercial applications.

The 5V Crimp panels require a solid roof deck with a waterproof

membrane.

Double ribs on the panel edges create the classic 5V look and

conceal an anti-siphon channel.

Machine Shows

Application: