Primary Technology Parameters Product Line:

1. PU foam thickness: 16mm, aluminum and galvanized coil thickness

0.27-0.4mm

2. Linear Speed of production:About5-6 meters per minute

3. Maximum Roller Forming speed:6meters per minute

4. Reciprocating times of injection head per minute <60

5. Production type: totally continuous production with PLC

controlling

6. Composite structure:position fixed by double rubber tracker

7. Foaming system: totally automatically continuous foaming,

quantity of foaming could be stepless adjustable

8. Main Power of production 50KW9. Cutting: pneumatic piston driving, non-stop cutting via sliding

table

10. Electronic controlling system: full-frequency PLC controlling

system.

Machine List:

| NO. | Composing of product line | Details | Amount |

| 1 | Roll Forming Machine | For 383mm flat | 1 |

| 2 | De-coiler | 5 ton hydraulic decoiler | 1 |

| 3 | Embossing machine | For embossing patterns | 1 |

| 4 | Assembling machine | PU two component Liquid mixing and injecting section for foaming

low pressure | 1 |

|

| Pre-heating machine | 1 |

| | Laminating device | 1 |

| | Panel automatically cutting system | 1 |

| | Dust collector | 1 |

| | PU assembling conveyor system(rubber belt) | 1 |

| 5 | Secondary painting machine | Secondary painting machine | 1 |

| 6 | PLC control panel | Siemens | 1 |

| 7 | Passive out-table | 6 meters in length | 1 |

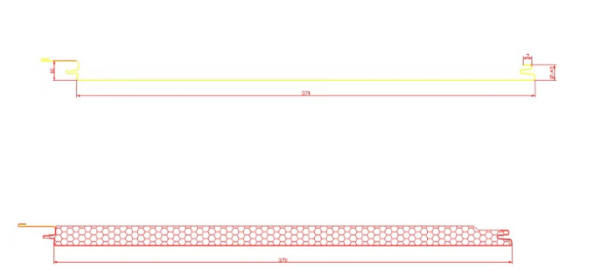

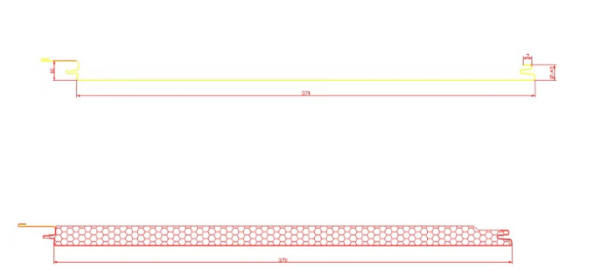

Roll Forming machine

A. 5 ton hydraulic De-coiler ---1 set

- Width of feeding:maximum 500mm

- Maximum loading coil weight :maximum 5000kg

- Inter diameter: 508-610mm

- Mode of expansion &tightness: automatic

- Way of feeding: automatic

B. Embossing machine

Picture is just for reference

- Main Roll Forming Machine

Each Roller forming machine consists of the decoiler, main roller

forming machine is equipped outside of the line, which is used to

form on the coil of color steel of maximum 500mm in width and

0.27~0.4mm in thickness while exerting certain pressing force.

1: Coil width: maximum 500mm effective width: 383mm

2: Working speed: 0-6 meters per minute

3: Roll station: About 18 stations

4: Material of roller: grade 45 steel, polished and coated with

chrome

5: Material of main shaft:45﹟forge steel diameter roller: Ф60mm

6: Main power: maximum 7.5KW

7: Forming thickness: 0.27mm—0.4mm , zinc and color steel, G250Mpa

8: Transmission: by single Chains 1 inch

9: Feeding and guide: surface polished and coated with chrome

10: Machine drive parts adopt protect cover

11: Machine adopt new station with chrome

12: Size of main machine: About 8750x1500x 1200(mm) L x W x H

13: Weight: about maximum 4000Kgs

14: Color of machine: blue (also can choose by customer request)

15: Machine should be with four legs (made from metal) in 350mm

Sample photo for reference:

Its fuction is to preheat the steel sheet.

- One Set of PU Foaming Machine

One set of PU two component Liquid mixing and injecting section for

foaming : it adopts high pressure pump. It have the temperature

control system and material-level monitoring system. The tank of

the material is about 300L./Two tanks. Injecting proportion is

A:B=1:125(A :black B:white ).

Sample photo for reference

1. Low pressure P.U. foam dispensing machine complete with:

VOLTAGE:THREE PHASE , 380V, 50HZ

2. 2 set of pumps mounted with separate motors

3. 1 set of Touch Screen Operator Panel with synoptic graphics and

alarm messages and 1 set of PLC

4. 2 set of flow transducers

5. 2 set of 300 liter pressurized carbon steel Jacketed tank

6. 1 set of Temperature control system for each tank

7. 1 set of 2 component Mixing head:the mixing head speed can be

adjusted steplessly .

8. Injection section: it also can adjusted toward left, right,

front or back. There’s rail for all the movement.

Its function is to protect the sheet surface.

1. The PU sandwich panel is be conveyed by double rubber belt.

2. The length of the BELT machine is about 22m, which consists of

upper frame and lower frame, each frame has two sections.

3. The width of rubber board is 1mm, the range of adjusting

distance between upper and lower rubber board: 300-500mm.

Sample photo for reference:

- Panel automatically cutting system

1. Cutting adopts tracking cutting.

2. Fly saw of the cutting machine can move transversely 500mm,

Cutting machine moves longitudinally and transversely along the

slide way.

3. Cutting machine adopts one-side blade band saw manner, cutting

and revolving after cutting. The cutting saw can revolve, so

cutting in two directions is realizable.

4. There is panel tight-pressing system (pneumatic) in the cutting

machine;

5. There is location limiter to limit longitudinal and transverse

motion of cutting machine.

Dust collector

Its function is to suck away the waste generated during cutting.

6 meters passive out table

PLC control system

- Power supplier: 380V, 50 Hz, 3Phase

- Length & quantity measurement automatically

(3) Length & quantity controlled by PLC

(4) Length inaccuracy can be amended easily

(5) Unit of length: millimeter (switched on the control panel)

Spare parts for free

| Name | Number |

| Tools | Feeler gauge | 1 |

| Size spanner | 1 |

| Inner hexagon spanner | 1 |

| Clamp | 1 |

| Standard spanner | 1 |

| Shifting spanner | 1 |

| Slotted screwdriver | 1 |

| Other accessories | Chain | 2 pieces |

| Bearing | 2 pieces |