Gauge 18-Gauge 24 J Square Trim Cornerbead Roll Forming Machine J

Channel Flush Metal Making MachineTrim

J, L and U Trim are metal trim accessories used to protect free

edges of gypsum wallboards.

Super Stud metal J, L and U-Trims is used at the termination of a

gypsum board finished wall or ceiling. This may be at a door or

window opening, at a transition to a different type of finish, or

at any edge where a clean, straight, smooth edge is required.

J Trim is used to cap raw panel edges where run-off is not a

problem. Most commonly, j trim metal is used to cap the top edges

of skirting, the top and sides of doors, the bottom and sides of

windows, and in many cases the top of windows for aesthetics and

continuity.

"J” square trim cornerbead was designed to cap drywall for a

professionally finished drywall edge.“J” square trim profiles for a

wide variety of installation requirements (1/2″ or 5/8″ flanges).

Our hemmed edge provides for a quick installation. For a smooth

application,“J” square trim cornerbead does not contain any joint

compound holes. For maximum protection manufactures its “J” square

trim with its proprietary coated steel.

Technical Data:

| Items | Specifications |

| Material of coil | Material Thickness | 0.4-1mm galvanized sheet full hard 85-95, G550, PPGI |

| Forming system | Rolling Speed | 0-10 m/min( without the cutting time) |

| Roller Stations | About 16-18 stations |

| Roller Material | 45# Steel with quenching 60mm shaft

|

| Maim Motor Power | 5.5 kw |

| Hydraulic cutting Power | 4 kw |

| Bearing | Rubber sealing bearing |

Cutting system | Material Of Cutting | CR12 with quench treatment |

| Hardness | HRB85-95 |

| Tolerance | +-1.5mm |

| Cutting way | Stop cutting |

| Electrical control system | Electric Source | 220V, 60HZ,3 phase Also can satisfy Customer’s require |

| Control System | PLC Delta |

| Inverter | Delta |

| Weight | About 2.5 tons |

| Way Of Drive | 1 inch single chain |

| Size of machine | Length 3000mm* Width 800mm* Height 500m |

| MOTOR | Under the frame of the machine |

Machine List:

| 3 ton passive de-coiler | 1 set |

| Main roll forming machine | 1 set |

| Cutting device | 1 set |

| PLC Control box | 1 unit |

| Hydraulic station | 1 unit |

| Out table | 1 unit |

Working Flow:

Decoiler—feedingwithguide—Rollforming——Cutting—Products collecting

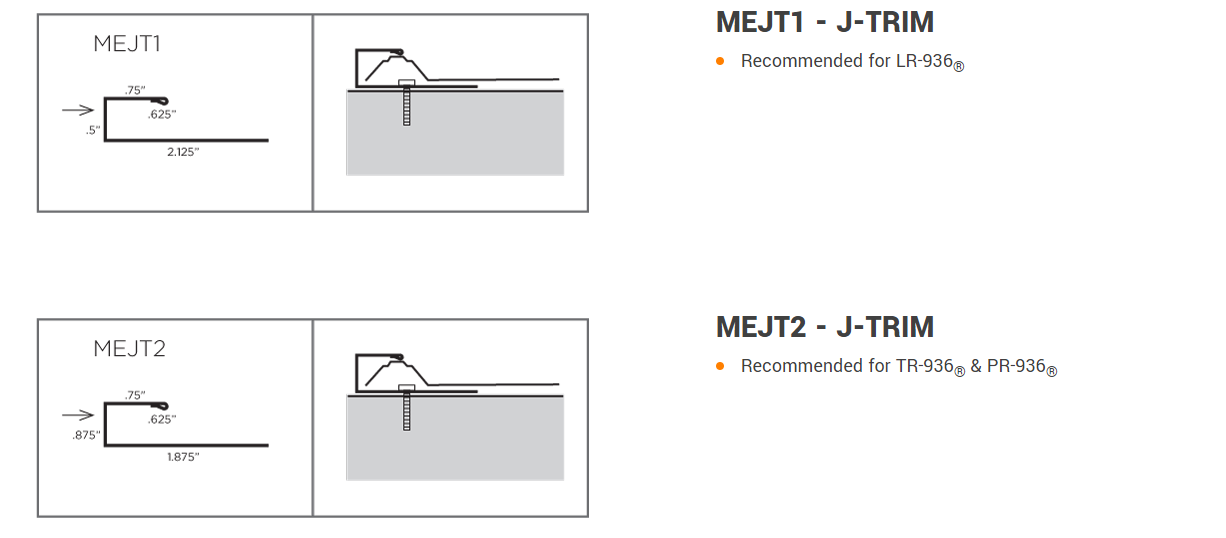

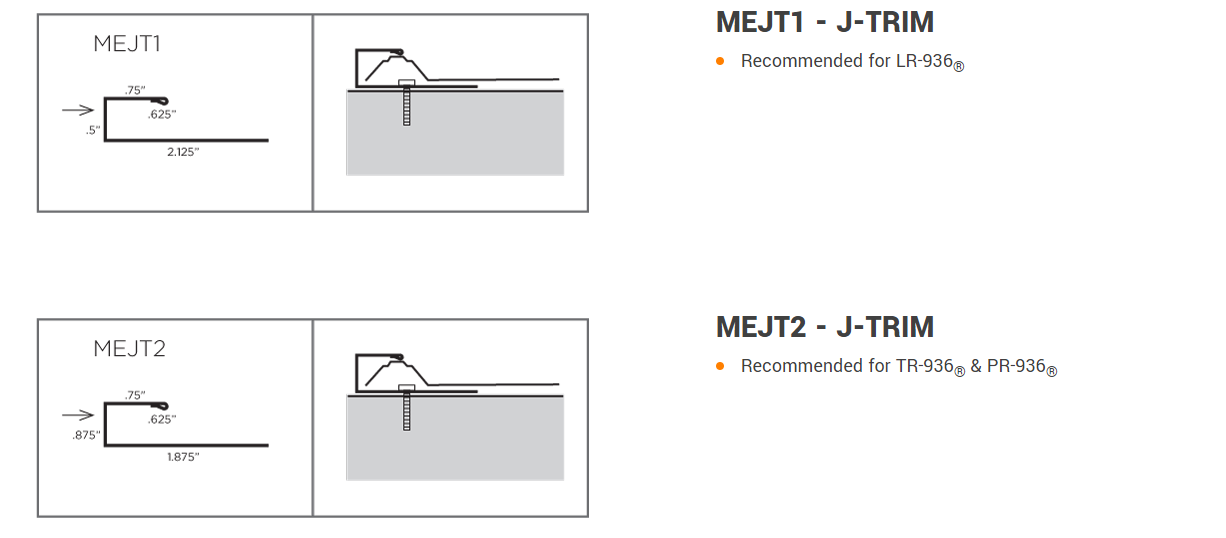

Profile Drawing:

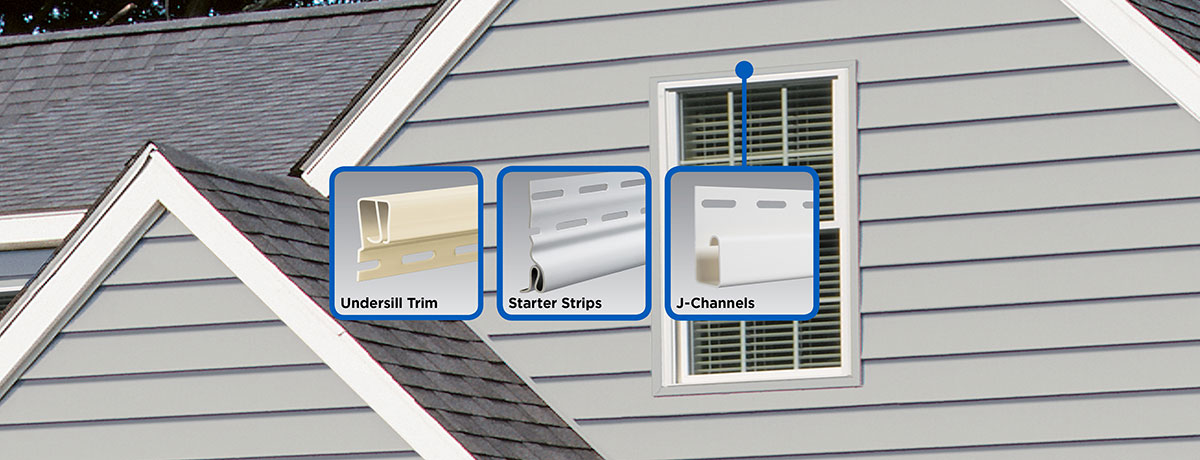

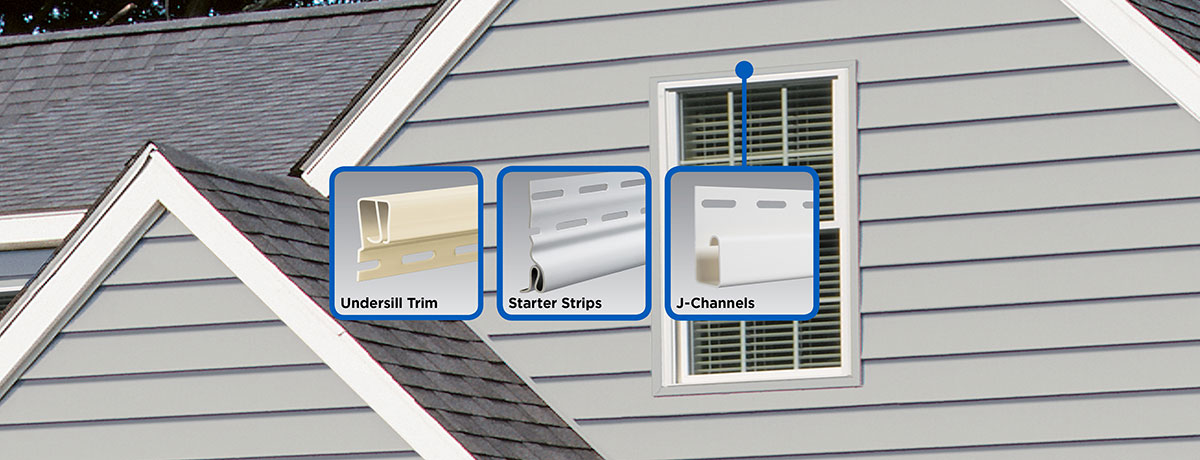

Application:

J-Trim

The short leg of Super Stud J-Trim is hemmed for a safe, clean,

smooth edge, and both legs are angled for a tight grip on gypsum or

other sheathing. The long leg has a slight rib at its base to act

as a screed for any finishes that are applied, and the outer edge

of the long leg has a small bevel for a smooth tight fit.

L-Trim

The short leg of Super Stud L-Trim is hemmed for a safe, clean,

smooth edge, and both legs are angled for a tight grip on gypsum or

other sheathing. The long leg is knurled and perforated and

specifically treated for optimal acceptance of gypsum– or

chemical-based joint compounds: with maximum adhesion and minimal

sag.

U-Trim

The knurled leg of our U-Trim has a smooth, dull finish,

specifically treated and perforated for optimal acceptance of

gypsum– or chemical-based joint compounds: with maximum adhesion

and minimal sag. U-Trim may be nailed, stapled, or screwed to the

gypsum, wood, or steel substrate.