Gear Box Driven Steel Barn Silo Metal Roof Roll Forming Machine

A. Main specification:

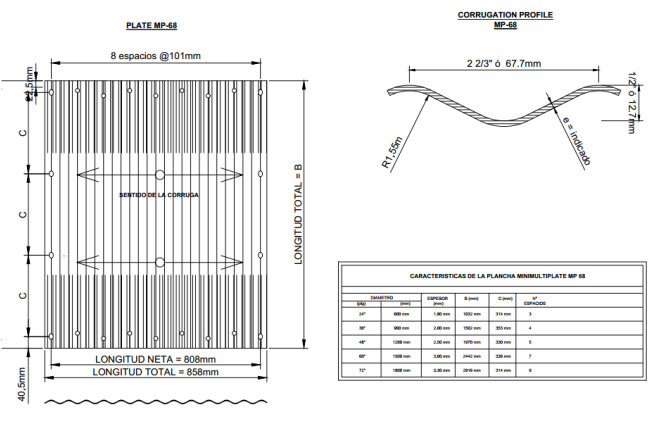

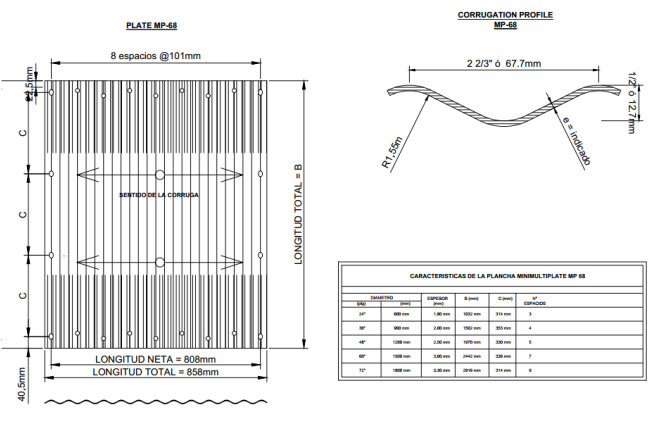

1. Materials to form shutter door: 1.5-3.3mm galvanized coils,

Feeding width: 914mm

2. Forming steps: about 18 stations

3. Material of rollers: Gcr15 steel precision-machined, high

frequency quenching HRC58-62,

4. Material of main shaft : 45# high quality steel (diameter>¢50)

5. Cutting: hydraulic cutting; quenching HRC58-62

6. Electronic control: PLC control Panasonic Brand

7. Dimension of machine: 11500mmX1350mmX800mm

8. Working speed:12-15m/min;

9. Drive system: gear box drive

10 main motor power: 90kw

11. Punching moulds: 3 sets of punching dies at one time

12. Curving machine: Curving continuously to make the sheets

straight, the min Radius 1.8m, the Radius can be adjustable.

13. Cutting: Hydraulic cutting

14. Hydraulic station power 55kw, the pressure 25-30Mpa.

15. Out table: lift auto stacker

16. Total Power 130kw

Machine List

| Number | Machine list | Number |

| 1 | 10 tons hydraulic de-coiler with coil car | 1 set |

| 2 | Feeding& leveling device | 1 set |

| 3 | Hydraulic punching device | 1 set |

| 4 | Main forming machine | 1 set |

| 5 | Hydraulic Curving &Cutting device | 1 set |

| 7 | PLC control system | 1 set |

| 8 | Hydraulic station | 1 set |

B. Working flow

De-coiler—feeding with guide→Straightening device→main rollforming

machine→Curving device→run out table

C: TRANSPORTATION

All goods will be shipped to your country, containers number will

be decided with how many machines you would choose

. Installation of the machine

The individual components of the machine are installed according to

the layout and prepared for the commissioning.

The installation comprises of:

- Installation by Sussman service technicians.

- The following services are included:

- Installation of the machine components.

- Adjustment of the machine components.

- Connection of all motors to the control cabinet.

- Installation of the required safety devices.

Delivery extent does not comprise of:

- Media supply (electrics, compressed air, etc.)to the

machine(control cabinet)

- Raw material process material and fuels

- Raw material for test blocks

- Transport and lifting devices

- Auxiliary staff.

The operators of the plant should be present during the

installation in order to become familiar with the new machines.

D. Commissioning of the machine

The components of the machine are commissioned one after the other.

At the end of the commissioning the machine is ready for production

and is handed over.

The commissioning comprises:

- Commissioning by Sussman service technicians

- Training at the machine

- The following services are rendered

- Run up of the machine components

- Testing of all functions of the machine components

- Start of a fully automatic molding process

- Execution of machine acceptance

Delivery extent does not comprise of:

- Raw materials, process materials and consumables

- Raw material for test blocks

- Transport and lifting devices

The operators of the plant should be present during the

commissioning in order to become familiar with the new machines.