1.5-2.0mm Automatic Racking Beam Box Beam Roll Forming Machine

Box beam roll forming machine is developed to produce the beam, it

is fixed between the upright rack post

It normally have two types: 1) both C beams are roll formed on a

roll forming machine then joint in a combined roll former to get a

box beam;

2) one beam is formed on a roll forming machine directly to get a

box beam.

The equipment is consisted of hydraulic de-coiler, roll forming

machine, servo following cutting section, Auto upside down, fold

machine and electrical control system etc.

Rack Beam Machine Main Specifications

1. Suitable Plate Material: thickness 1.2-2mm black steel

2. Forming speed: 0~15M/Min

3. Forming machine: about 19 stations+5 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal

refining

6. Driven system: gear box driven

7. Main Power with reducer: 7.5*2KW

8. Cutting: Fly saw cutting

9. The whole machine is controlled by industry computer-PLC.

10 PLC--Siemens, English and Chinese Language

11. Touch Screen--Panasonic Japan

12. Encoder--Omron, Japan

13. Electric parts--Schneider

Rack Beam Machine’s Components

| S.N | Equipment name |

1 | 3T hydraulic un-coiler |

2 | Main roll forming machine |

3 | fly saw cutting |

4 | PLC Control system ( including control box) |

5 | 4meters passive out table |

6 | Auto Upside down device |

7 | Lock Joint machine |

9 | Safety Cover |

9 | Spare parts |

Working Flow of Rack Beam Machine

Hydraulic de-coiler-- roll forming machine --->cutting device

--->Auto upside down--> folded machine-Out table

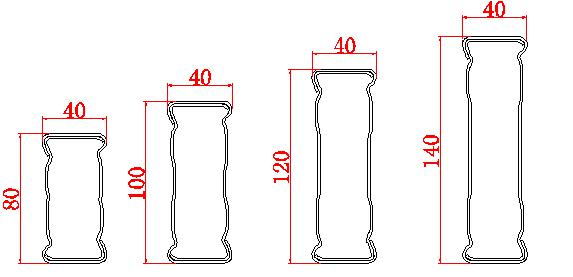

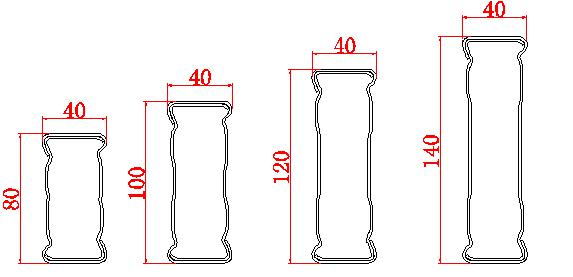

Rack Beam Profile reference

In warehouse pallet racking system, we are able to manufacture more

machines like Step beam roll forming machine, Upright rack roll

forming machine and shelf panel (box plate) roll forming machine

etc.

Roll forming machine included parts

1. 3 ton hydraulic De-coiler

Diameter: 460-520mm expansion.

Expansion: hydraulic

Capacity: 3000kg per mandrel

Max Coil Width: 500mm

Drag tension brake with variable brake tension adjustment valve

2. Main roll forming machine

3. Cutting: Fly saw cutting

Cutting after forming: Cut the sheet after roll forming to required

length, fly saw cutting

Cutting motion: The main machine automatically cut, and the cutter

will move on the guide rails forward and back non-stopping.

Length measuring: Automatic length measuring

Tolerance of length: 6m+/- 0.5mm

4.Auto upside down device

Maintance and the service of the machine

Daily maintenance with meticulous care plays an important part in

extension the equipments’ operation time and the quality of rolling

plank. Therefore, please do the following things in your daily

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil

before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving

chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work

outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when

you use next time.

4. If the equipment does not use for long time, you should use

plastics cloth or other articles to cover it and notice to avoid

rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to

the request

6. Usually look into hydraulic station and the oil quantity of

deceleration machine, you should add in time when oil quantity

shortage

7. Electrical components should be guaranteed to work in a dry

environment, such as damp. Rain should continue to work after

drying.