18 Stations Galvanized Steel 100-300mm Automatically Width And

Height Adjustable CZ Purlin Roll Forming Machine

A CZ purlin roll forming machine is a specialized piece of

equipment used in the construction industry to produce C and

Z-shaped purlins from metal coils. These purlins are essential

components in the structural framework of buildings, providing

support for roofs and walls in various structures including

industrial buildings, warehouses, and residential homes.

Key Components

1. Uncoiler: Feeds the metal coil into the machine.

2. Roll Forming Stations: Series of rollers that shape the metal

into C or Z profiles.

3. Punching Unit: Creates holes in the purlins for fastening.

4. Cutting System: Cuts the formed purlins to the required lengths.

5. Stacker: Collects and organizes the finished purlins.

6. Control System: Manages the entire process, ensuring precision

and consistency.

Features and Capabilities

- Profile Production: Capable of producing C, Z, U, and Angle

shapes with quick changeovers between profiles.

- Adjustability: Features variable adjustments for different sizes

and thicknesses of purlins, typically ranging from 1.5mm to 3.0mm

in thickness.

- Automation Levels: Available in semi-automatic and fully

automatic variants, with fully automatic machines offering higher

efficiency and productivity.

- Speed and Efficiency: High-speed production capabilities, with

some machines achieving speeds up to 30 meters per minute.

Industrial Applications

CZ purlin machines are widely used in various construction sectors:

- Building Construction: For roofs and walls in warehouses,

factories, shopping centers, and homes.

- Infrastructure Projects: Such as bridges and transportation

terminals.

- Solar Power Structures: Providing support frameworks for solar

panels.

Considerations for Choosing a Machine

When selecting a CZ purlin roll forming machine, consider the

production capacity, the types and sizes of purlins needed, the

material thickness, the level of automation, and the reputation of

the manufacturer. These factors influence the machine's

performance, cost, and suitability for specific applications.

Overall, investing in a CZ purlin roll forming machine can

significantly enhance the efficiency and quality of purlin

production, essential for modern construction projects.

Technicial Speciafication

| Material | PI; PPGI |

| Thickness | 1.5-3.0 mm |

| Forming Speed | 15m/min |

| Roller stations | 20 stations |

| Roller material | Cr15 to be quenched |

| Main motor | 11kw |

| Hydraulic cutting power | 7.5kw |

| Control system | PLC |

| Dimension | 10.3×1.5×1.2m |

| Driving system | Chain |

| Tolerance | ±1.5mm |

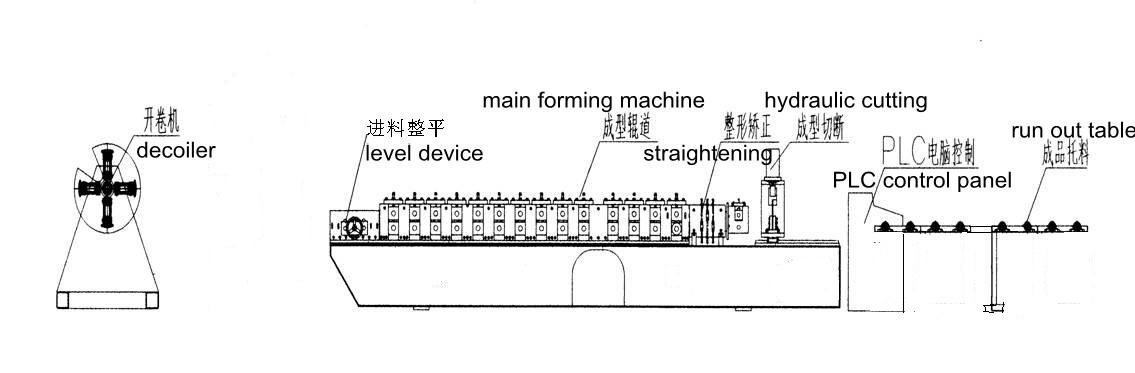

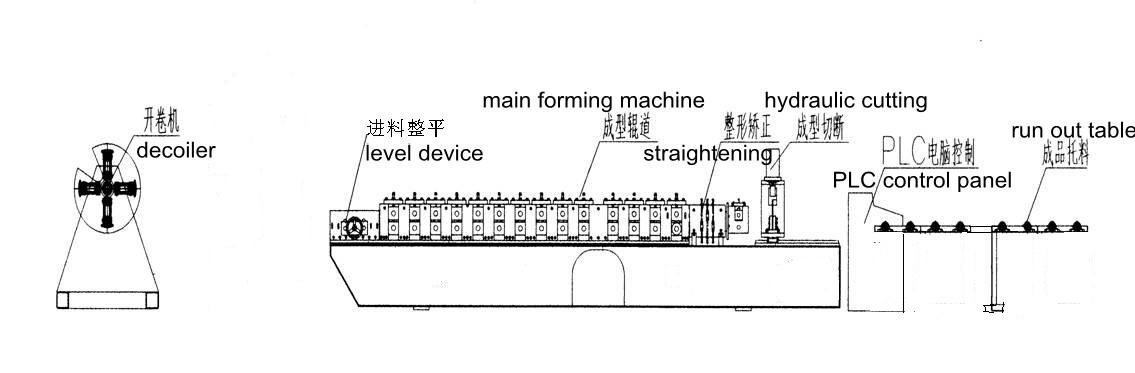

Working Flow

Decoiler—→level device—→main forming

machine—→straightening—→hydraulic Punching —→hydraulic cutting—→

run out table

Machine List

| 3 ton passive Uncoiler | 1 set |

| Main roll forming machine | 1 set |

| Control box | 1 unit |

| Hydraulic station | 1 unit |

| Out table 1500mm | 2 units |

| Hydraulic punching and cutting device | 2 units |

| Hydraulic cutting device | 1 unit |

Main Components of the Machine

1. Hydraulic Decoiler with Breaking device is equipped for coil

processing.

2. Leveler

3. Hydraulic punching system

4. Pre Shearing System

5. Rollformer with tooling

6. Run Out Table or automatic stacking device

7. Panasonic (Japan) PLC and MCGS touch screen are used for data

processing and setting.

8. Roll forming speed is 8 - 12m / min.

Profiles

C PURLIN SIZES

Width: C80-300

Thickness: 1.5-3.0mm

Height: 40-100mm

Control Box: Panasonic Brand

(1) Power supplier: 415V, 50 Hz, 3Phase (adjusted with the

requestment)

(2) Length & quantity measurement automatically;

(3) Length & quantity controlled by PLC,

(4) Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7) The language in the touch screen: English and Chinese

(8) Unit of length: millimeter (switched on the control panel)

Out Table

Length : 2m

Quantity: 2 units

Pictures of the product: